Level Measurement

Level, interface and volume measurement for basic, challenging, and extreme conditions in any application.

Our wide range of level transmitters, detectors, switches and accessories for liquids and solids measurement will help you to optimize processes and improve safety at your plant, from the most challenging and extreme applications with viscous, corrosive and aggressive media to the simplest ones.

Gain ease-of-use, reliability and accuracy with Emerson's Rosemount level measurement sensors and technologies.

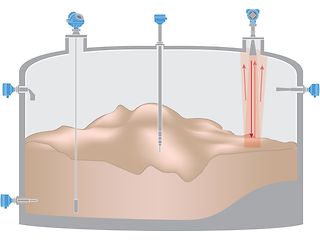

Guided Wave Radar Level Transmitters utilize microwave technology to measure continuous level and interface level of liquids, solids, and slurries. Emerson’s market-leading portfolio offers accurate, reliable, safe and cost-effective level measurement, even in the most challenging process conditions. Powerful onboard diagnostics give insight into device health and signal quality, giving you peace of mind your process is under control.

Non-contacting radar level transmitters measure the continuous level of liquids or solids in small and large tanks, vessels and open-air applications across many different industries. From the most challenging applications that require highly accurate level measurements to the simplest applications, our radar sensors will help you to gain efficiency and improve safety at your plant, while offering you ease-of-use, reliability and accuracy.

Differential Pressure (DP) Level Measurement uses pressure readings and specific gravity to output level. DP Level is a common measurement technique that is used in a wide variety of applications and industries. Solutions include standard transmitter connections and integrated transmitters with direct or remote mount seals that can be configured in tuned, balanced, and electronic systems. Additional Wireless options are also available.

Magnetic level technology provides robust, low maintenance measurement in oil and gas, petrochemical and power applications. Rosemount™ 9930 Magnetic Level Indicators may be used as a replacement for sight glasses and to add redundancy when used as a complete level solution alongside the Rosemount™ 5300 Guided Wave Radar Level Transmitter and Rosemount™ 9935 Level Bypass Chamber. Emerson’s portfolio also includes Magnetostrictive Transmitters and Magnetic Level Switches, providing flexible level detection in many installation types.

Liquid level switches measure point level within a vessel. Emerson’s portfolio is based on vibrating fork technology and offers a safe, reliable and cost-effective solution in most liquid applications such as high-low level monitoring, pump control, critical alarms and overfill prevention. Switches may be installed for primary monitoring or control, or alongside other level technology providing redundancy and reducing risk.

Solids Level Switches are a reliable and cost-effective point level solution to detect the presence or absence of solid media in a variety of applications, such as in the food and beverage industry, chemical processing, and wastewater treatment. Emerson’s portfolio includes vibrating fork and rod technology, paddle switch and capacitance technology, providing easy-to-install and accurate level measurement and control in different media types and process conditions.

Gain additional capabilities and ensure you are maximizing the power of your level measurement devices with Rosemount software and accessories.

Emerson’s portfolio of level accessories include bypass chambers and controllers plus a wide range of spare parts such as electronics cassettes, antenna kits and adapters. Our accessories help you optimize your operations by streamlining maintenance, upgrade and repair of your level instruments, and offer you flexibility to adapt our products to your specific needs.

Tank gauging is the measurement of liquids in large storage tanks with the purpose of quantifying the volume and mass of the product in the tanks. It is your go-to solution for accurate inventory management, reliable overfill prevention (IEC 61508 certified SIL2/SIL3) and custody transfer aligned with OIML and API Standards.

The Rosemount Tank Monitoring System offers a cost-effective way to monitor liquid level, temperature and volume for inventory control.

With flexibility to connect a range of different instruments, the system can be tailored to each tank – regardless of tank size, shape, or contents.

When integrated with our inventory management software, the system provides insights on your product inventory, helps reduce manual measurements, improves accuracy, and prevents tank overfill.

The Rosemount™ Remote Tank Monitoring system is a user-friendly asset monitoring logistic solution that will help you manage all your assets from one point, regardless of their location. The system comprises the Rosemount™ 408 Wireless Level Sensor and the Plantweb™ Insight Tank Application software monitoring level, temperature, and GPS location. This provides operational insights to enable better-informed strategic decisions and improved business performance.

Built to withstand harsh marine environments, our monitoring systems feature rugged durability and advanced level, pressure, and temperature transmitters for precise readings even in challenging conditions. This robustness is complemented by an easy installation process and minimal maintenance, saving time and resources. These systems also ensure full regulatory compliance, whether you need traditional cargo monitoring (CMS) or a fuel or custody transfer measurement system (CTMS).