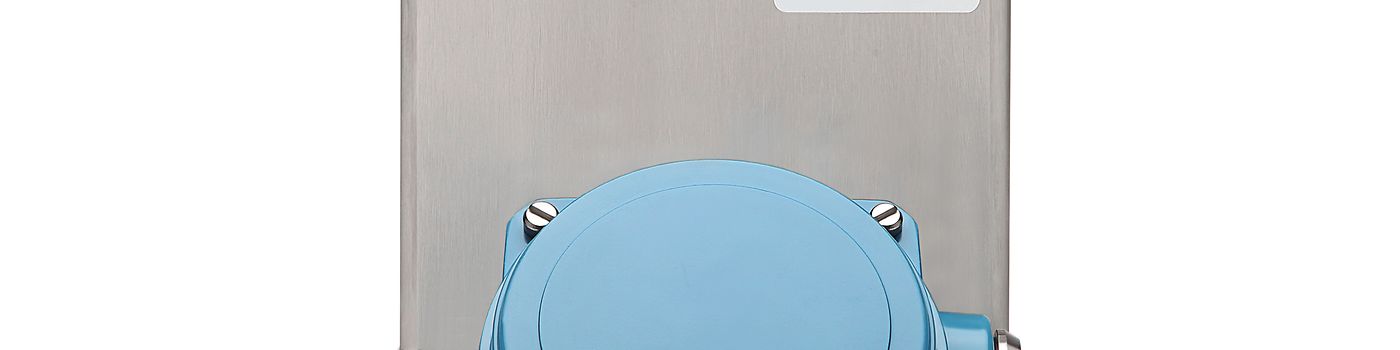

Micro Motion High-Pressure Coriolis (HPC) Series Meter Consisting of HPC015P and 2400 Transmitter

Specifications

Micro Motion HPC015P Coriolis Meter, 1/8 INCH (DN3), stainless steel, 15,375 psi (1060 bar) maximum operating pressure

- Flow Rate

- Up to 504 kg/hr (1110 lb/hr)

- Liquid Mass Flow Acccuracy

- Up to±0.1% of rate

- Liquid Mass Flow Repeatability

- Up to±0.05% of rate

- Gas Mass Flow Accuracy

- ±0.5% of rate

- Gas Mass Flow Repeatability

- ±0.25% of rate

- Liquid Density Accuracy

- up to ± 0.001 g/cc at standard conditions

- Fluid temperature Range

- -46 C to 200 C (-50 - 392 F)

- Pressure Range

- 0-15,374 psi (0-1,060 bar)

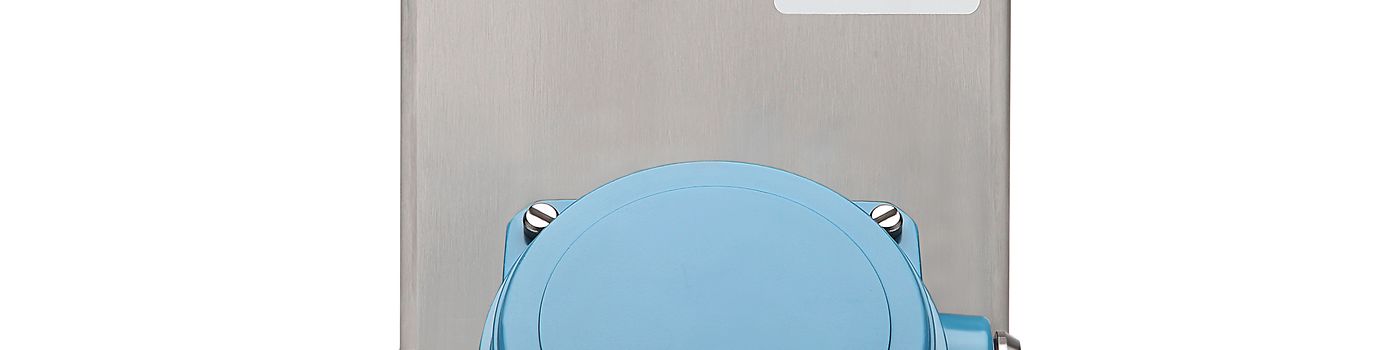

Micro Motion 2400S Compact, Integral-Mount Transmitter

- Output variables

-

Mass & volume flow

Net product content / flow

Temperature

Density

Concentration

- Local display

-

Standard user interface with 2-line LCD panel

Two clips for HART/Bell 202 connections (requires removing transmitter housing cover)

Two membrane pushbuttons for local operation (requires removing transmitter housing cover)

Glass or plastic lens options

- Power

-

Self-switching AC/DC input, automatically recognizes supply voltage

85–265 VAC, 50/60 Hz, 4 watts typical, 7 watts maximum

18–100 VDC, 4 watts typical, 7 watts maximum

Complies with low voltage directive 2006/95/EC per EN 61010-1 (IEC 61010-1) and Installation (Overvoltage) Category II, Pollution Degree 2

- Input/output signals (analog output option)

-

Channel A:

One active 4–20 mA output

Not intrinsically safeChannel B (configurable), one of:

One active or passive frequency output

One active or passive discrete output

One active or passive discrete input

- Input/output signals (PROFIBUS-DP option)

-

Digital 2-way PROFIBUS-DP signal

- Input/output signals (DeviceNet option)

-

Digital 2-way DeviceNet signal (Now Obsolete)

- HART

-

Bell 202 signal is superimposed on the primary milliamp output

HART communication is not available on PROFIBUS-DP and DeviceNet transmitter versions

- Mounting options

-

Field mount, integral with sensor

- Application types

-

Continuous process control

Two-phase flow/entrained gas

Meter verification

- Hazardous approvals

-

C1D2

Zone 2

Features

Micro Motion HPC015P Coriolis Meter, 1/8 INCH (DN3), stainless steel, 15,375 psi (1060 bar) maximum operating pressure

-

- Realize superior performance in high-pressure applications

- Use one device for reliable and repeatable mass flow, volume flow, density, concentration and temperature measurement

- Get the best real-world Coriolis performance at operating pressures up to 15,374 psi (0-1,060 bar)

- Minimize maintenance and boost long-term reliability with no moving parts to wear or replace

- Maximize uptime using Smart Meter Verification to check system integrity without need to pull meter out of service

- Accommodate any installation requirement with available two-wire, direct-connect (no transmitter needed), stainless steel and 5700 transmitters

- Dramatically reduce operating expenses for chemical injection and hydrogen dispensers.

Micro Motion 2400S Compact, Integral-Mount Transmitter

-

- Receive diagnostics for performance under entrained gas and batching from empty applications with MVD digital processing

- Gain real-time and in-process measurement integrity assurance with Smart Meter Verification

- Employ the best two-phase flow capability for batching, loading and entrained gas applications

- Eliminate the need to remove the transmitter cover with optical buttons on the display

- Rely on Class 1, Div. 2 (Zone 2 ) hazardous area approval (sensor and transmitter )

Documents & Drawings

Micro Motion HPC015P Coriolis Meter, 1/8 INCH (DN3), stainless steel, 15,375 psi (1060 bar) maximum operating pressure

Micro Motion 2400S Compact, Integral-Mount Transmitter